The NHERI Lehigh EF is housed in the Multi-directional Experimental Laboratory at the ATLSS Engineering Research Center, Lehigh University. The ATLSS Laboratory has a strong floor that measures 31.1m x 15.2 m in plan, and a multi-directional reaction wall that measures up to 15.2 m in height. Anchor points are spaced on a 1.5-m grid along the floor and walls. Each anchor point can resist 1.33 MN tension force and 2.22 MN shear force. Additional steel framing is used in combination with the strong floor and reaction walls to create a wide variety of test configurations. A 178-kN capacity overhead crane services the test area and an adjacent fabrication area. Additional smaller cranes with capacities of 45-kN and 27-kN also serve this area. The ATLSS Laboratory has a machine shop and material testing facilities.

The Lehigh NHERI EF equipment portfolio includes the following:

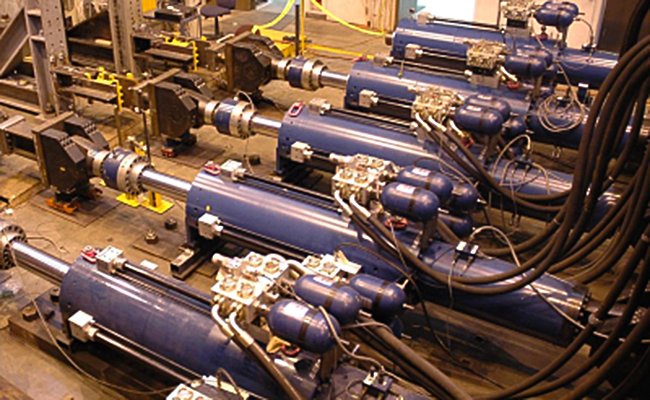

Five dynamic, double rodded hydraulic actuators designed and manufactured by Servotest Systems:

Two 2300 kN dynamic actuators ported for three 2080 liters/min (550 gpm) servo-valves, +/- 500 mm stroke

Three 1700 kN dynamic actuators ported for three 2080 liters/min servo-valves, +/- 500 mm stroke.

The maximum velocity that can be achieved by these actuators is 840 mm/sec (2300 kN actuators) and 1140 mm/sec (1700 kN actuators).

Ten three-stage 2080 liters/min high flow-rate servo-valves. Ten service manifolds, with a low-pressure and high-pressure setting, to operate at 24.2 MPa and a maximum flow of 2080 liters/min. All manufactured by Servotest.

Three MTS DuraGlide 244.21 Hydraulic Actuators

Two two-stage 50 kN dynamic actuators ported for two 55 liters/min (15 gpm) servo-valves, +/- 250 mm stroke

One three-stage 50 kN dynamic actuators ported for one 340 liters/min (90 gpm) servo-valve, +/- 175 mm stroke

Two MTS service manifolds, with a low-pressure and high-pressure setting, to operate at 21 MPa and a maximum flow of 189 liters/min and 378 liters/min.

Hydraulic pump and oil reserve and two banks of accumulators that enables strong ground motion effects to be sustained for up to 30 seconds.

Five pump 2270 liter/min (600 gpm) hydraulic system.

Accumulators supply a total accumulated oil volume of 3030 liters connected to the hydraulic pressure line.

Dedicated connections for the high-flow hydraulic service manifolds and return line from these dedicated connections to the pump house area.

Hydraulic oil reservoir in the pump house area for the oil needed to fill the accumulators and to receive the return flow, and connections to the reservoirs, heat exchangers, and pumps.

Two Servotest Pulsar distributed high-performance, real-time digital servo-control systems for test and motion simulation.

Servo-drive PID control and command generation with feedback signal conditioning using fiber-optic based actuator & analogue node modules.

Hydraulic supply control, rig safety and digital I/O connections via a robust hydraulic control and safety node

High speed 384-channel data acquisition system manufactured by Pacific Instruments, capable of acquiring data up to 4096 Hz (4096 samples per second) per channel.

Synology network attached storage system with dual-redundancy data protection and daily mirroring to Designsafe-CI

Conventional sensors, including temposonic displacement sensors of +/-750mm and +/-1120mm stroke, triaxial and monoaxial +/- 10g accelerometers, and bi-axis dynamic 360 degree inclinometers

Two Blue Iris web camera systems capable of streaming and recording 4K HD video and time-lapse images from over twenty IP web cameras.

Amcrest UltraHD 4K (8MP) Bullet POE IP Camera, 3840x2160, 131ft NightVision, 2.8mm Lens

Amcrest 4K Optical Zoom IP Camera, Varifocal 8MP Outdoor POE Camera Bullet, 2.7mm~13.5mm Lens

Amcrest ProHD 1080P POE (Power Over Ethernet) IP Camera with Pan/Tilt, Full HD (1920TVL) @ 30FPS, Wide 90° Viewing Angle and Night Vision

Sony SNC-EP550 720p/30 FPS PTZ IP PoE Camera

In addition to the above equipment, ATLSS has 27 existing actuators that can be used for static load applications (e.g., to apply gravity load to test specimens). These actuators range in capacity from 130 kN to 2680 kN.

Advanced sensors are also available from ATLSS that include two digital image correlation (DIC) systems that can perform non-contact 3-D full-field strain measurements under dynamic loading. The measurement volume range is 10 x 7.5 mm to 2000 x 1500 mm, and the strain measurement range is from 0.01% to 100%. The maximum sampling rate is 500 frames/sec.

Auxiliary equipment that includes 180 kN and 90 kN overhead cranes, forklifts, man lifts, and a machine shop.