CMMI 2036131 - PI Nikos Makris, Southern Methodist University

Project Overview:

The increasing need for structures to meet acceptable performance levels during earthquake and wind excitations has led to the development of various high-performance design and retrofit strategies. Supplemental damping is a widely accepted response-modification strategy for structures where energy is dissipated in dedicated, specially designed energy dissipation devices. Motivated by the recent failures and displacement limitations of existing energy dissipation devices, this project examines experimentally the behavior of a pressurized sand damper, an innovative, reliable, long-stroke and low-cost energy dissipation device; as well as the seismic hazard mitigation of a fully sustainable wall-damper system that is comprised of a CLT rocking wall structure and of the pressurized sand damper, through real-time hybrid simulations (RTHS) and large-scale experimental testing.

Research Methodology and Outcomes:

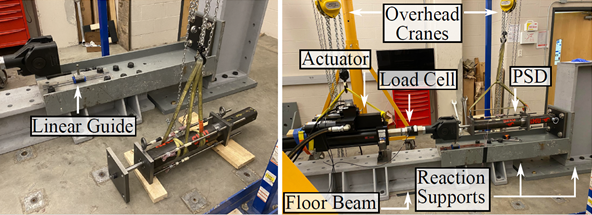

This fourfold project involves the component testing of the pressurized sand damper that has been conducted in the Structures Laboratory of Southern Methodist University with a 55-kip actuator, as can be seen in Fig. 1. The second area of investigation involved the robustness of the proposed pressurized sand damper when installed in harsh environments with either high or low temperatures. This stage of the project involved the use of thermocouples, as well as heating and cooling approaches. That was an experimental campaign that took place in the Natural Hazards Engineering Research Infrastructure (NHERI) Lehigh Experimental Facility (EF) at Advanced Technology for Large Structural Systems (ATLSS) Engineering Research Center, at Lehigh University. The third stage of the project included the RTHS of a CLT rocking wallpressurized sand damper system.

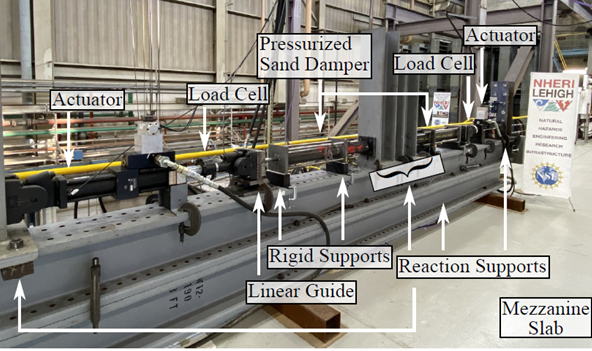

The CLT rocking wall constituted the analytical substructure, while two customized double-ended pressurized sand dampers, which were designed and built in the SMU Structures Laboratories, constituted the experimental substructure. Figure 2 illustrates the setup of the two customized double-ended pressurized sand dampers for the RTHS that took place at the NHERI Lehigh EF at ATLSS Engineering Research Center, at Lehigh University. The final stage of this projects involves the large-scale physical testing of a one-storey CLT structure with a rocking wall that is equipped with the two customized double-ended pressurized sand dampers. The two physical pressurized sand dampers will be coupled to the 5?8scale CLT rocking wall in the NHERI Lehigh EF at ATLSS Engineering Research Center, at Lehigh University.

Educational Impact:

One Ph.D. Candidate conducted their study on the development of the pressurized sand damper. Three of the four stages of this project are developed in their Ph.D. Thesis. The Ph.D. Candidate conducted the experimental work at the SMU Structures Laboratory, the analytical model that corresponds to the pressurized sand damper behavior, as well as the experimental work and the RTHS in the NHERI Lehigh Experimental Facility at ATLSS Engineering Research Center, at Lehigh University. Four REU students have participated in the project, gaining value experiences in analytical approaches, component testing, and RTHS approaches.

Outcomes

The outcomes of this project include (1) the better understanding of the effect of the design parameters of the damper, (2) the development of the analytical model that can be implemented in the different FEA software and represent the pressurized sand damper behavior, (3) the effect of the supplemental damping offered by the pressurized sand dampers to rocking wall systems through RTHS and physical large-scale testing, and (4) the robustness of the pressurized sand dampers in harsh environments with either high or low temperatures. At least half a dozen publications in peer reviewed journals and more than ten conference presentations will be the outcome of this project.